The Digital Load Test

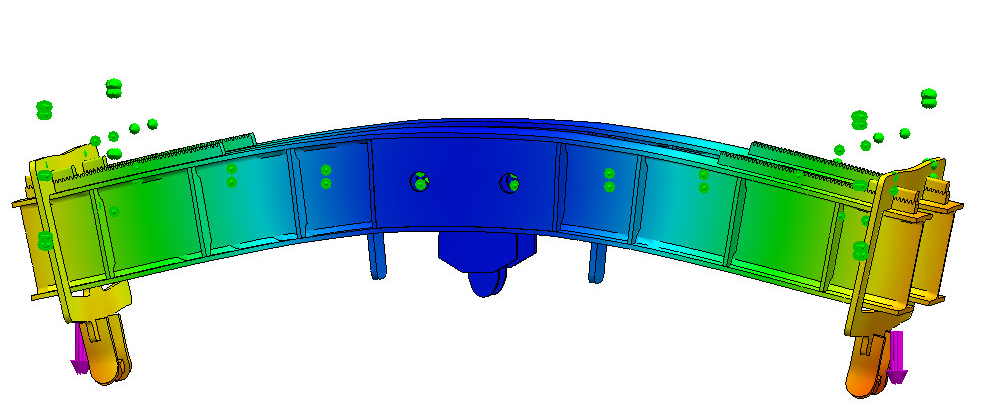

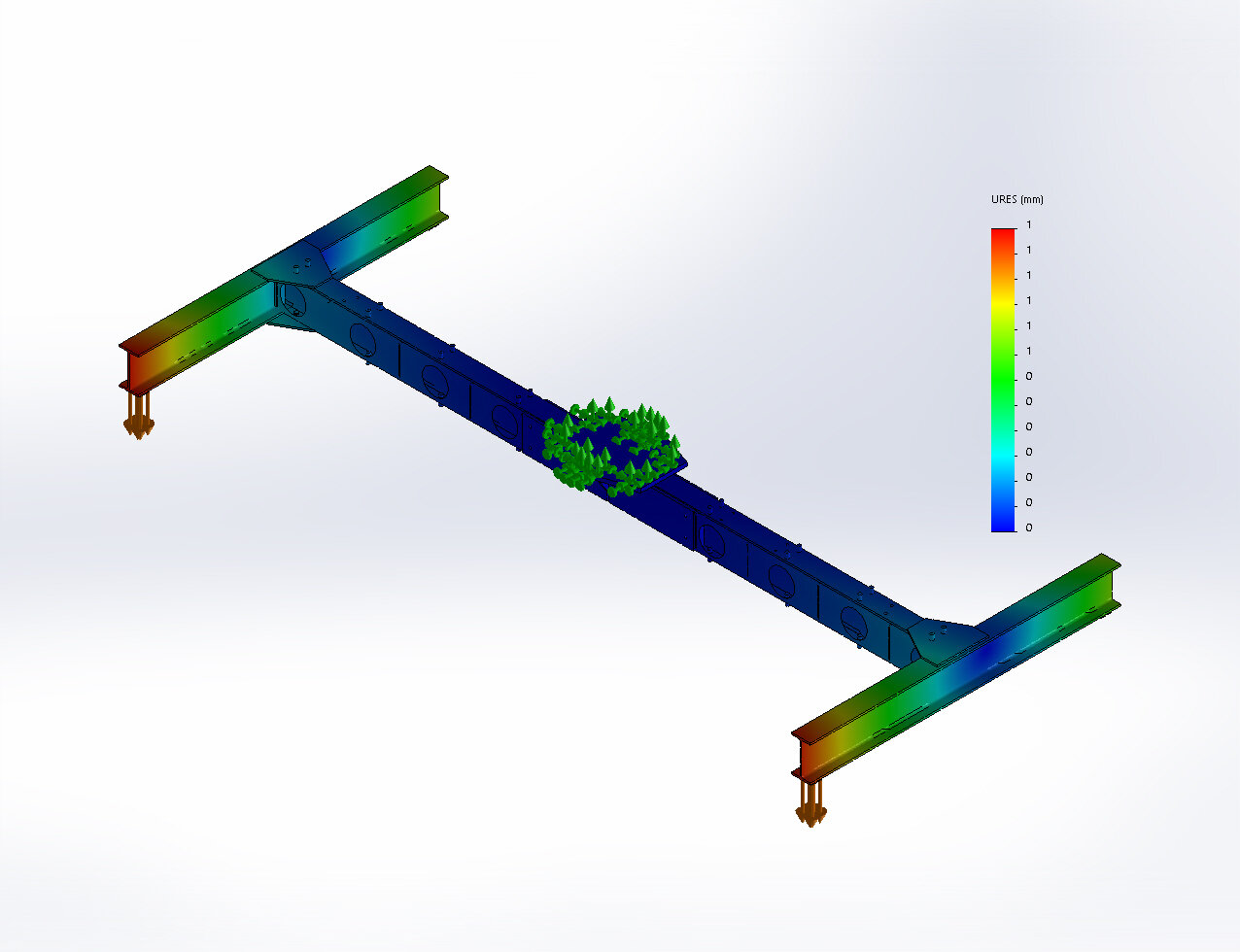

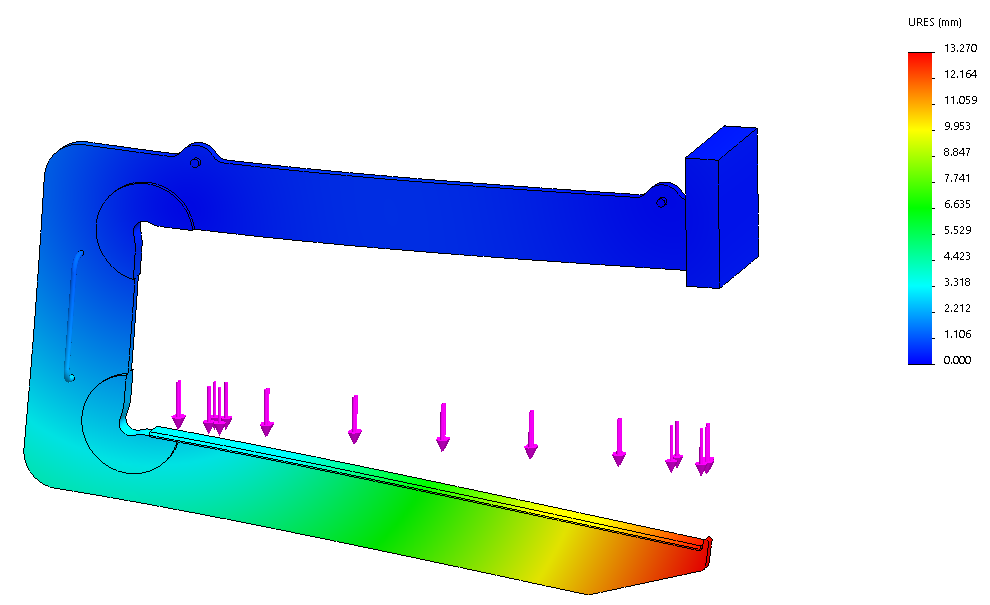

3D Simulation by CERTEX

The advantages of simulation by using the Finite Element Method FEM have become an integral part of engineering and development and are indispensable. Whether for individual component loads, geometry variations or material changes, flexible investigations of the design are easier to realize.

With FEM simulation, our engineers are able to simulate mechanical deformations, vibrations or rotations under a wide range of physical conditions. Among the most important advantages of the FEM method are component optimizations and strength verifications. Both the smallest and the largest components can be analyzed. Particularly advantageous with the FEM method is, among other things, the reduction in the number of physical prototypes required, since these are digtially replaced.

At CERTEX, we can subject your load handling device to an FEM simulation, so that you benefit not only from the most accurate analysis results, but also from cost savings (through material reduction, for example) and lower inherent weight of the design.

Save costs and development time. With FEM, possible design errors, deformations, tensions, etc. can be detected in advance and prevented accordingly. Profit from weight and stiffness optimization of components. Your design to be examined will be simulated by our competent and experienced engineers at the highest quality and safety standards.

Ready for a digital load test?

Discover the digital simulation of your lifting device now.