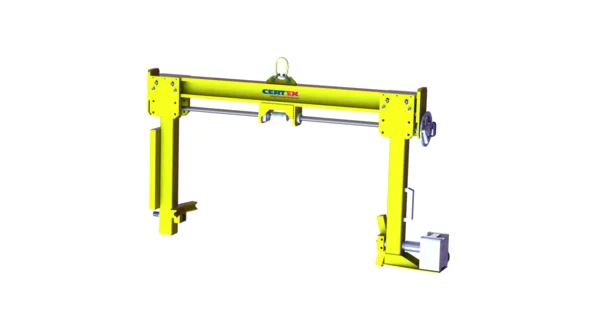

Gripper - For lifting loads

Grippers mainly use two gripping principles: Form-fit or force-fit.

Form-fit grippers grip around or under the load to be lifted or grip into a recess and thus create a mechanical connection.

Force-fit grippers create the connection through friction, suction or magnetic force. They must be dimensioned in such a way that they have a safety factor of 2 against loosening under load. They must also be secured against slipping or falling (e.g. by bolting or screwing) if this is not guaranteed by the type of load suspension.

A form-fit gripper must never be used as a force-fit gripper, as its contact pressure is too weak and the load can slip out of the gripper. When using force-locking load handling attachments without additional protection against the load falling, the load must not be passed over people.

|

A special type of gripper is the reversible gripper: Reversible grippers are available with positive or non-positive engagement. The load's center of gravity must be in the axis of rotation, otherwise large restoring forces can occur! These can cause the load to tip over (tipping impact), causing the gripped item to fall and/or the maximum load on the gripper to be exceeded. Particular care must be taken when emptying containers to ensure that the center of gravity does not change. There is a serious risk of injury! |

|