The Powertex LP582 eye nut is the most simple and essential product in our range of lifting points. It is designed to permanently attach equipment such as motors, control cabinets, and gearboxes. This lifting point ensures reliable performance and safety in your operations but also has some limitations. As it is a fixed lifting eye, we recommend it primarily for straight single-point lift. The lifting point shall be screwed tightly to the structure or load. Please check other products in our range for more advanced and versatile lifting points.

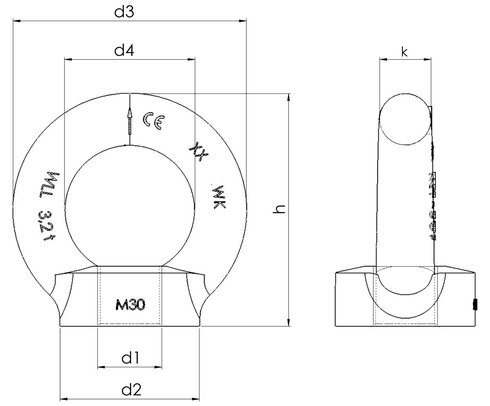

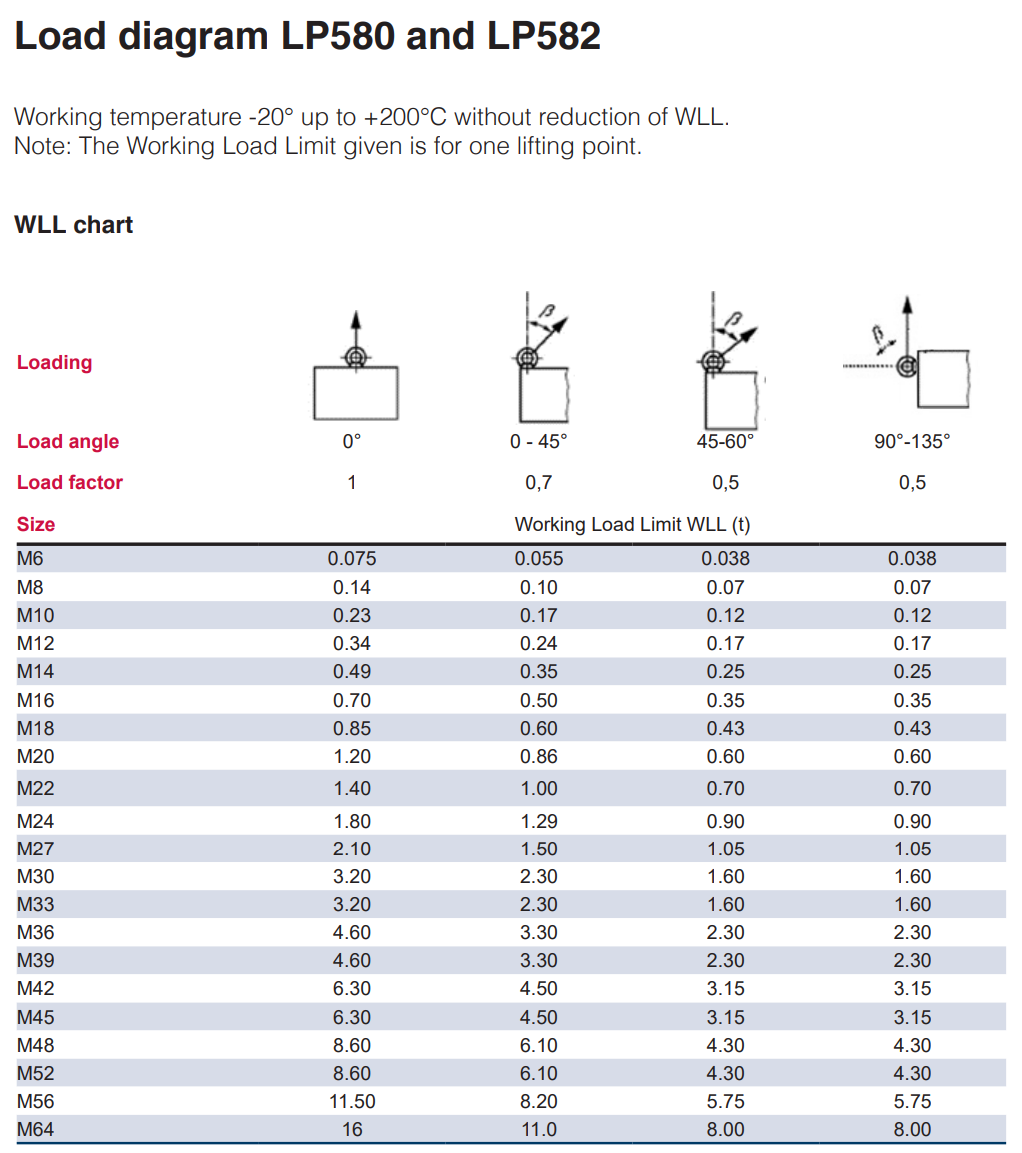

Allowed Loading Directions:

- Straight (max WLL)

- Sideways (not perpendicular to the eye)

- 180 degrees in the plane of the eye (+/- 90 degrees from centre line)

- Check the WLL Table for proper WLL reductions when loading sideways

Product Features:

- Durable finish: electro galvanized (Chrome 6 Free)

- Compliance to standard: manufactured to meet the testing requirements specified by DIN582, ensuring high safety and quality standards.

- Reliable: designed with a safety factor of 6:1 in the intended load directions, offering a secure lifting experience.

- Quality assurance: samples are load tested in the factory to ensure high reliability.

- Full traceability: every component is marked with PX branding, WLL, CE mark, Size, Material (C15E), and a traceability code, ensuring traceability to the production lot and raw materials.

- WLL indication: the LP582 is marked with the WLL (straight loading 0°) and an arrow that shows the corresponding load direction. The WLL chart provides an applicable WLL for other loading directions.

- Harmless: Chromium 6 free, aligning with environmental safety standards.

- Certificates included: each box includes a POWERTEX 2.2 certificate and a Declaration of Conformity confirming compliance with EC and UK regulations.

- Wide temperature range: allowed for use between -20°C to +200°C without WLL reduction.

- Material: Carbon Steel C15E

- Marking: According to standard, CE-marked, UKCA-marked, PX, Material, WLL, Nominal size, Batch number, Arrow indicating the axial direction

- Temperature range: -20°C up to +200°C

- Finish: Electro galvanized

- Standard: DIN 582

- Note: The lifting eyes shall be screwed tight against the surface. Reduce WLL when not loading straight (see table).

- Safety factor: 6:1