Enhance your lifting and handling operations with the POWERTEX Weld-on Hook WH, a robust and reliable solution for welded mounting on lifting beams, excavators, and other earth-moving machinery. Engineered to meet the rigorous demands of industrial environments, the WH hook ensures secure and efficient load handling.

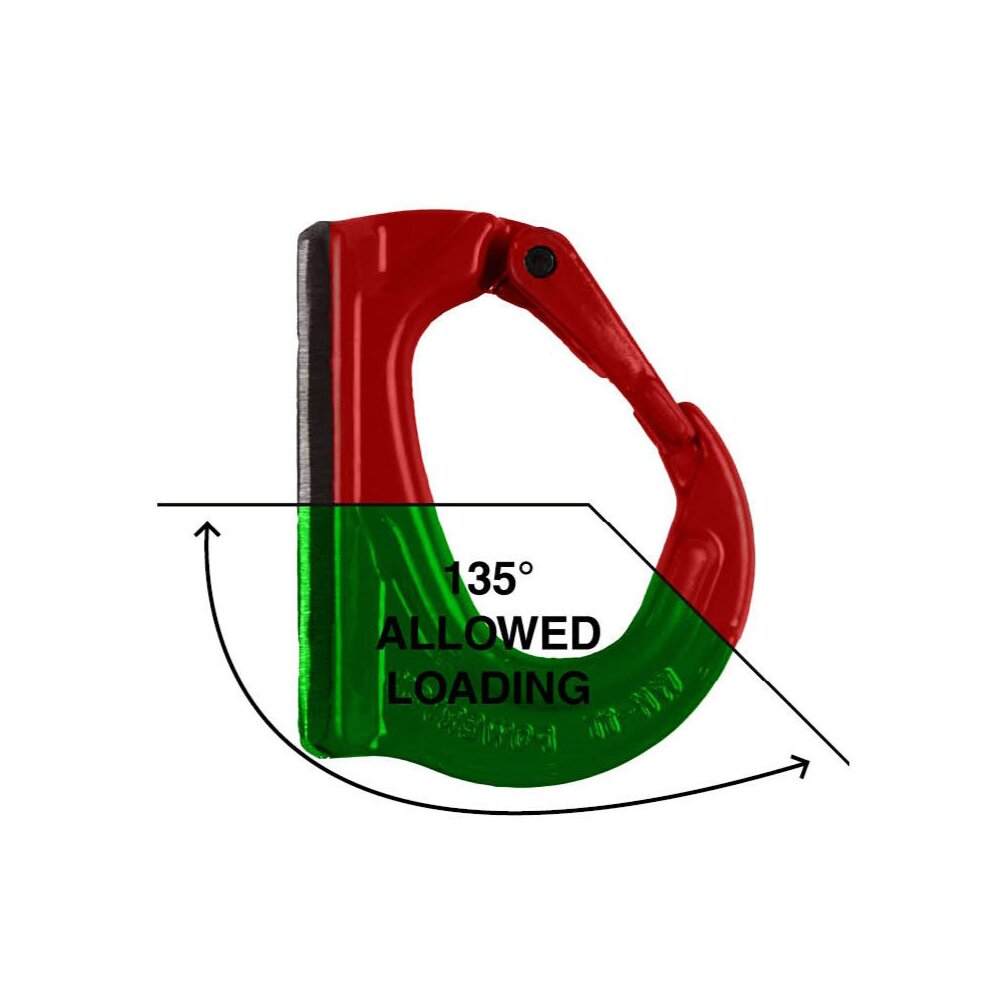

Allowed loading directions:

- The WH hook is designed to be loaded within a 135-degree area in the intended load plane (+45 to -90 degrees from the weld-on surface)

Product features

- Durable Finish: Coated in PURE RED powder paint, the WH Weld-on hooks stand out for their durability and corrosion resistance.

- Ready for welding: The weld base is not painted, allowing for immediate welding without excessive smoke or fumes.

- Compliance to standard: Manufactured to meet the testing requirements specified by EN 1677-1, ensuring high safety and quality standards.

- Reliable: Designed with a safety factor of at least 4 in the intended load directions, offering a secure lifting experience. Safety factor of 5 when loaded parallel to the weld base.

- Quality assurance: Each component undergoes crack detection testing and sample proof loading in the factory.

- Type Testing: Each model undergoes factory type testing, including breaking tests and a fatigue test to 20,000 cycles at 1.5 times the WLL, which highlights the product's endurance.

- Full Traceability: Every component is marked with POWERTEX branding, model name, WLL, CE-mark, UKCA-mark, and a traceability code, ensuring traceability to the production lot and raw materials.

- Harmless: Chromium 6 free, aligning with environmental safety standards.

- Certificates Included: Comes with a POWERTEX 2.2 certificate & Declaration of Conformity with each box, confirming compliance with EC and UK regulations.

- Wide Temperature Range: Optimized for use between -40°C to +200°C without WLL reduction, with permissible WLL reductions for higher temperature ranges, ensuring adaptability to various environments.

- Features: Weldable base prepared for immediate welding, spart part kits available

- Material: Forged Alloy Steel

- Marking: CE-marked, UKCA-marked, POWERTEX, model name, WLL and batch number

- Temperature range: -40°C up to +200°C

- Finish: Powder painted in PURE RED

- Note: The LPW is WLL (Working Load Limit) rated, assuming that the correct welding procedure is meticulously followed and executed by a suitably qualified welder, to maintain the product's integrity and compliance with safety regulations.